The basis for safe system operation in potentially explosive areas

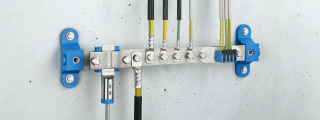

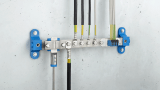

Equipotential bonding systems form the basis for safe system operation.

To eliminate potential differences and prevent dangerous touch voltages, all electrically conductive parts must be connected to the equipotential bonding.

Lightning currents are particularly dangerous in hazardous areas.

To ensure that employees and facilities remain safe, the operator is obliged to provide protection in this area.

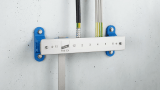

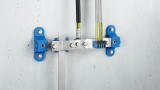

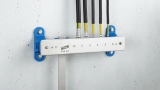

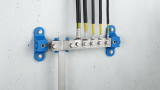

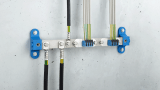

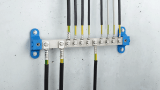

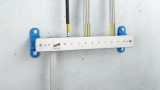

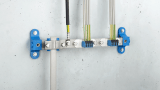

Non-sparking - tested with lightning currents

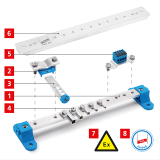

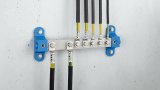

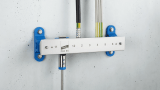

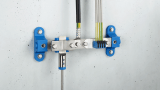

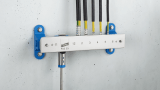

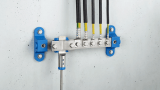

You can use the new PAS EX equipotential bonding bars in Ex zones 1/21 and 2/22. They work in a non-sparking manner and their connections are secured against self-loosening.

Good to know:

- The absence of ignition sparking in case of lightning current was tested in a gas atmosphere in cooperation with an external test laboratory.

- PAS EX can also be used in applications with hydrogen.

/www.dehn-international.com/store/f/40550049/HDVORSCHAU/472411a1_16-9.jpg)

/www.dehn-international.com/store/f/40550124/HDVORSCHAU/472411.jpg)

/www.dehn-international.com/store/f/40550141/HDVORSCHAU/472421.jpg)

/www.dehn-international.com/store/f/40550101/HDVORSCHAU/472410.jpg)

/www.dehn-international.com/store/f/40550112/HDVORSCHAU/472420.jpg)

/www.dehn-international.com/store/f/40550060/HDVORSCHAU/472415.jpg)

/www.dehn-international.com/store/f/40550087/HDVORSCHAU/472425.jpg)